520M LOADER

Loader

- Diverter kit allows for a 3rd function loader, eliminating additional cost of purchasing kit elsewhere

- Available single-point hydraulic connection saves time

- Hydraulics that improve cycle times and productivity

- Integrated parking stands for easy attachment and removal

Features

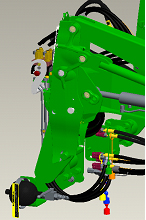

Single-point hydraulic connection on row-crop tractor (closed)

Single-point hydraulic connection on row-crop tractor (closed) Single-point hydraulic connection on utility tractor (closed)

Single-point hydraulic connection on utility tractor (closed)The 520M, H240, 540M, H260, and H310 Loaders can be configured with a single-point hydraulic connection that also incorporates the connection point for any electrical needs. To disconnect the hydraulic connection between the loader and the tractor, it is necessary to relieve the hydraulic system oil pressure on the tractor.

Parking stands

Parking stands

John Deere loaders are easily removed and reinstalled on tractors without tools. The parking system allows removing or attaching the loader to the tractor in minutes without the need for tools.

To remove or park the loader, apply slight down pressure to the loader boom with the bucket dumped at approximately a 30-degree angle. With the tractor in park, lower the parking stands and place the mast pins in the open position.

To watch a video of parking and attaching an M- or H-Series loader click here.

Removing or parking the loader

Parking stand in stored position

Parking stand in stored position Removing parking stand

Removing parking stand Mast pin in the closed position

Mast pin in the closed position Rotating mast pin to the open position

Rotating mast pin to the open positionUtilizing the boom circuit with the tractor in neutral, rotate the mast forward until the mast has rotated past the pin location on the mounting frame by extending the lift cylinder. Using the bucket circuit, roll back the bucket until the mast is removed from the pocket and will clear the tires.

Mast pin in the open position

Mast pin in the open position Masts rotate forward, then bucket rolled back

Masts rotate forward, then bucket rolled backWith the tractor in park, shut the engine off and relieve the hydraulic pressure as indicated for the tractor (rotating the joystick). Disconnect or open the single-point hydraulic connector (or remove couplers if no single point is installed).

Disconnect/open single-point hydraulic connection

Disconnect/open single-point hydraulic connection Disconnect/open single-point hydraulic connections

Disconnect/open single-point hydraulic connectionsStore the loader half of the single-point connector or hoses, and back away from the loader.

Single-point hydraulics disconnected

Single-point hydraulics disconnected

Parked loader

Parked loader Hydraulic shut-off valve (open position)

Hydraulic shut-off valve (open position) Hydraulic shut-off valve (closed position)

Hydraulic shut-off valve (closed position)A hydraulic shut-off valve is included with the M- and H-Series Ag Loaders to ensure the loader does not lower suddenly. For example, this allows the boom to be locked out when someone is required to be located under the loader boom for service work on the tractor. It should not be used for extended periods of time unless an appropriate support stand is also utilized.

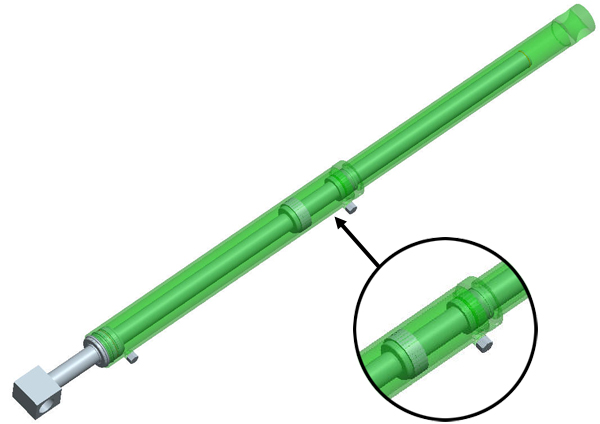

False rod cylinder

False rod cylinder

Fast bucket cycle times are important to dump the load from the bucket as quickly as possible, (quite often) in order to be as productive as possible, while completing loading operations. The bucket cylinder design can have a major impact on this cycle time, especially for the mechanical self-leveling (MSL) loaders.

Therefore, all MSL 520M and H-Series Loaders utilize false rod bucket cylinders. A false rod cylinder has a smaller displacement of oil requirement on the head end of the cylinder, which allows this cylinder to dump much faster than a normal cylinder.

Nitrogen-charged accumulator and electric valve

Nitrogen-charged accumulator and electric valve Operator on/off switch

Operator on/off switch LSS on H180

LSS on H180 LSS on 5E and 5M

LSS on 5E and 5MAn enhancement to the loader is the suspension system. A great level of loader productivity is achieved with the LSS.

- An accumulator charged with nitrogen and connected to the head-end lift cylinder hose through a T-fitting provides shock absorption

- The cylinders move in and out to allow the boom to float

Performance

- Bales can be transported more efficiently from one end of the field to the other over frozen, hard-packed, or rutted terrain.

NOTE: Check bale-handling capability of tractor before use.

- Pallets can be moved easily without sustaining cargo damage

- Pallets of seed or fertilizer can be carried across a yard without a bag spilling and creating a costly mess

- Properly ballasted tractor with LSS has increased stability, creating a smoother ride for the operator

Cost of ownership

- Extended life of loader pins and bushings

- Less stress on tractor axle

Reasons for turning LSS off include:

- Digging applications - with LSS on, the cylinders retract slightly, losing lifting power

- Holding a grade when blading - with LSS on, it is difficult to hold a constant grade

- Precise pallet and bale handling - with LSS on, the load moves up and down slightly while being positioned

- Parking a loader - with LSS on, when down pressure is applied, the lift cylinders retract slightly, making it more difficult to park

The switch is conveniently located in the operator station to avoid having to exit the operator station to manually move the handle on the LSS.

LSS can also be ordered with a manual shutoff. Depending on the tractor/loader model, the accumulator is located in different places. On the H180, the accumulator is mounted outside the bottom of the mounting frame. On the 5 Series Tractors, the accumulator is mounted near the inside of the rear right wheel. On 6 Series Tractors and larger, it is mounted in between the hydraulic connection and the mounting frame.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 520m-loader Current Model |

|---|---|

| Maximum lift height (A) | 3234 mm 127 in. |

| Lift capacity at full height | Measured at pivot (U) 1219 kg 2687 lb |

| Boom breakout force | Measured at pivot (Y) 2060 kgf 4542 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 3092 kgf 6817 lbf |

| Clearance at full height - bucket dumped (C) | 2415.1 mm 95.1 in. |

| Dump angle, degrees (E) | -53 degree (angle) |

| Rollback angle, degrees (G) | 47 degree (angle) |

| Tractor | |

| Model | 5220, 5320, 5420, 5520 |

| Front tire | 320/85 R24 BKT (12.4 R24) |

| Rear tire | 420/85 R30 BTK (16.9) |

| Front axle configuration | |

| Wheelbase | 85.7 in. |

| Pump capacity | 11 gpm |

| Rated pressure | 2828 psi |

| Loader | |

| Base weight | 826.9 kg |

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | General Purpose 1850 mm 73 in. |

| Bucket weight | 178 kg 392 lb |

| Lift capacity at full height | Measured at pivot (U) 1219 kg 2687 lb Measured at 800 mm ahead of pivot (V) 1404 kg 3095 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 1598 kg 3523 lb Measured at 800 mm ahead of pivot (X) 1555 kg 3428 lb |

| Boom breakout force | Measured at pivot (Y) 2060 kgf 4542 lbf Measured at 800 mm ahead of pivot (Z) 1774 kgf 3911 lbf |

| Bucket rollback force capacity | At maximum height (VV) 1780 kgf 3924 lbf At 59-in. (1500-mm) lift height (XX) 3014 kgf 6645 lbf At ground-level line (ZZ) 3092 kgf 6817 lbf |

| Dimensions | Maximum lift height (A) 3234 mm 127 in. At full height - bucket level(B) 3039 mm 120 in. At full height - bucket dumped (C) 2415.1 mm 95.1 in. |

| Overall length (I+F), ft (m) | 4.3 m 14.3 ft |

| Overall height in carry position (J) | |

| Digging depth (H) | 181.6 mm 7.1 in. |

| Reach | At maximum height (D) 759.8 mm 29.9 in. At ground level - bucket level (F) 2164 mm 85 in. |

| Bucket angle | Dump angle, degrees (E) -53 degree (angle) Rollback angle, degrees (G) 47 degree (angle) Dump angle, ground -105.7 degree (angle) |

| Cycle times | Loader raise, seconds 3.3 seconds Loader lower, seconds 2.2 seconds Bucket dump, seconds 2.6 seconds Bucket rollback, seconds 2.6 seconds |